Lubrication Systems Manufacturer

Our Strategic Approach to Lubrication Management

Industrial Innovations has over 40 years of experience in offering spray lubrication solutions including mixing, application, and reclamation. We are your complete source for Sustainable Lubrication Management.

Proportional Mixing

The Pro-Mix™ system offers consistent, precise lubricant mixing in a variety of styles to meet any size facility needs…

Learn MoreApplication

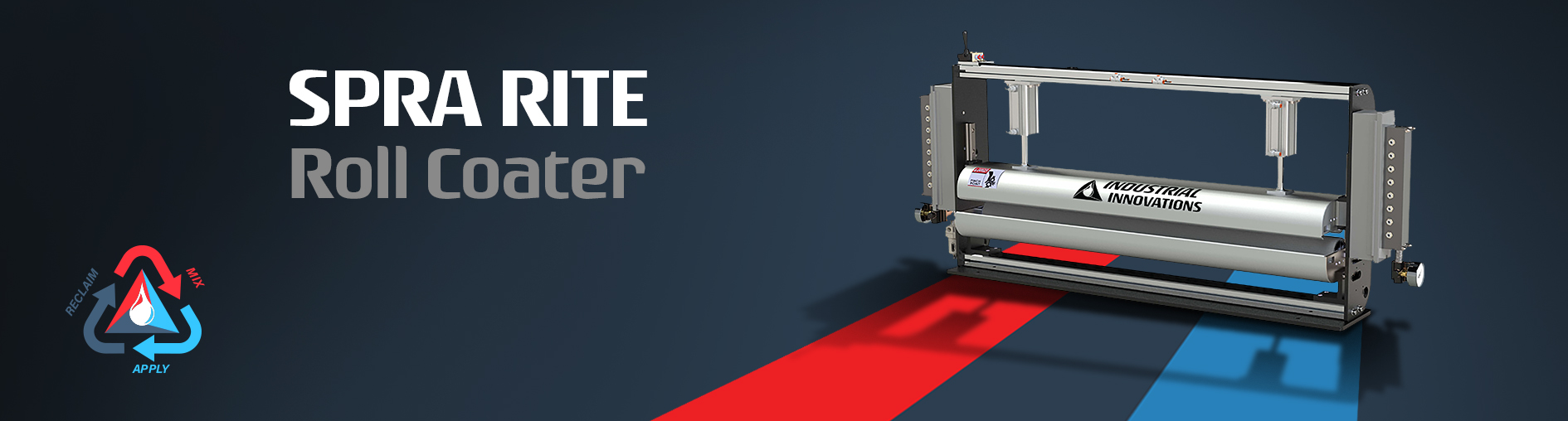

Accurate application of lubricants is essential to the functionality of its use. Utilizing our Spra-Rite™ technology,…

Learn MoreReclamation

The Reclaim-Pro™ purification and recycling units are water and oil separators, helping to reduce lubrication requirements…

Learn More

Automation

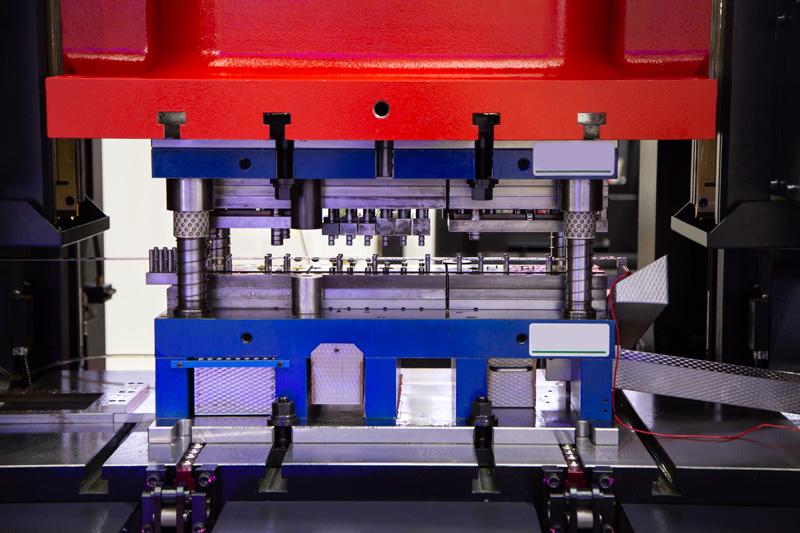

Industrial Innovations is proud to be a key part of FANUC’s Authorized System Integrator (ASI) Network for automation systems. Our team is experienced in delivering the highest quality automated lubrication systems from concept to final installation including 3D robotic simulation.

Industries Served

Industrial Innovations has the know-how across a wide range of metalworking sectors to optimize and manage lubrication programs for improved operations. As your spray lubrication & automation system manufacturer help boost productivity, improve die and tool life, achieve consistent part quality, and reduce your lubrication and removal fees.

About Us

Industrial Innovations is a Michigan-based spray lubrication system manufacturing company providing strategic lubrication management systems and automation solutions for industrial environments throughout North America. In addition, our Advance Automation products offer casting companies die spraying, extraction, and ladling technology.